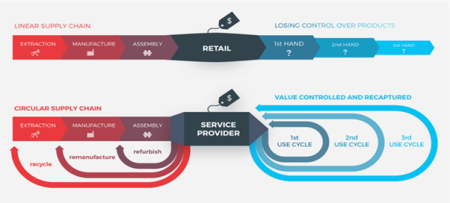

A linear economy and a circular economy are fundamentally different. Simply put, in a linear economy, raw materials are mined, turned into a product, and then disposed of after use. We close the cycles of all these basic resources in a circular economy.

Recycling alone won’t be enough to complete these cycles. It modifies how value is produced and maintained, how production is made more sustainably, and which business models are employed.

Having said that, this blog will contrast the two economies and show how Econocom has incorporated the circular economy into its services.

Linear economy

The take-make-dispose model is used in classic linear economies.

This mode of production emphasises the use of acquired raw materials before converting them into products, consequently discarding unwanted materials.

The value of a linear economy is produced by mass manufacturing and product sales by many companies. The linear economy is known as the ‘open cycle’ because of its plan, which is identical to a flat line.

The primary issue with this kind of manufacturing is the illogical use of limited resources. Resources are usually not used in the final product of the production process. This has a combined negative effect since it has a detrimental impact on both the environment and climate change.

According to Impax, the linear economy depletes raw materials and energy, resulting in CO2 emissions. Statistically, approximately 68% of input raw materials are non-renewable, posing a serious problem and threat to the environment considering that these products are either destroyed or burned.

More than 160 million new laptops are manufactured each year. The production and materials needed to make the motherboard, SSD, and display account for the majority of a laptop’s emissions, which range from 75% – 85% of its entire carbon footprint.

Additionally, in the EU alone, 160,000 “old” laptops are discarded daily. This is crucial since the cycle of disposing of old laptops and purchasing new ones is repeated. 70% of those laptops could be recycled, repaired, or remanufactured, lowering the need for raw materials, energy, and waste disposal.

Circular economy

The circular economy is far more worthwhile and sustainable than the linear economy. The fundamental goal of this economy is to keep material’s added value while reducing waste as much as feasible. It focuses on utilising products as resources. The 3R initiative (reduce, reuse, and recycle) is the main approach utilised by the circular economy.

Throughout manufacturing, for example, exhausted resources are utilised to the greatest extent possible, while old, used products are reused to the greatest extent possible.

Given this, the transition from a linear to a circular economy should be maintained to ensure that humanity advances in a sustainable manner.

Nearly all devices will be reused in a circular economy. A device will be repaired if it malfunctions. When that isn’t feasible, new products are created from it. Waste serves as the new raw material in the circular economy. The old order of production, consumption and disposal is no longer in effect.

This minimises CO2 emissions while also preserving raw materials and the environment. It also encourages employment, new business ventures, and innovation.

So, what’s the difference?

| Linear | Circular | |

| Step plan | Take-make-dispose | Reduce-reuse-recycle |

| Focus | Eco-Efficiency | Eco-Effectivity |

| System boundaries | Short-term, from purchase to sales | Long-term, multiple life cycles |

| Reuse | Downcycling | Upcycling, cascading and high-grade recycling. |

| Business model | Focuses on products | Focuses on services |

Source: KENNISKAARTEN

The linear economy focuses on products, whereas the circular economy focuses on services. This is the major distinction between the two economies.

The circular model of manufacturing is eco-effective, in contrast to the linear model, which is eco-efficient since it supplies the market.

The linear economy is set up so that raw materials are extracted, produced into goods or products, used, and then discarded. To put it another way, this model is founded on the idea of “disposability” and uses a lot of resources and energy.

The circular economy varies fundamentally from the traditional model in that it views the product as a good that may be revalued or rethought to maximise its valuable service lifespan. Raw material overuse is minimised by restoring recycled, re-used, and re-manufactured materials into the system, thereby closing the circle.

How Econocom has adopted the circular economy concept

A provider of circular economy solutions will make every effort to extend the lifespan of its products. By fixing it, reusing some of its components in subsequent manufacturing runs, and ultimately recycling it, it should extend its lifespan.

With rental and service options that include trade-in and further loops, Econocom creates financing solutions appropriate for circular business models. We want to make the process from ownership to use as simple as possible for businesses and governments.

By subscribing to a maintenance service, you’re committed to managing your IT infrastructure sustainably and minimising your ecological footprint from digital technology. With our solution ‘IT-as-a-service’, enterprises may finance circular economy initiatives without having to make a substantial initial payment. In addition to including life cycle services, they may also balance the cost by reducing the strain on CapEx while achieving the goals of the company.

Therefore, this relieves the business of the responsibility of taking money away from other services to maintain operations and agility. To finish the loop and provide value, the equipment will also be collected, discarded, and wiped as part of the subscription when the as-a-service contract expires.